Toolmaking

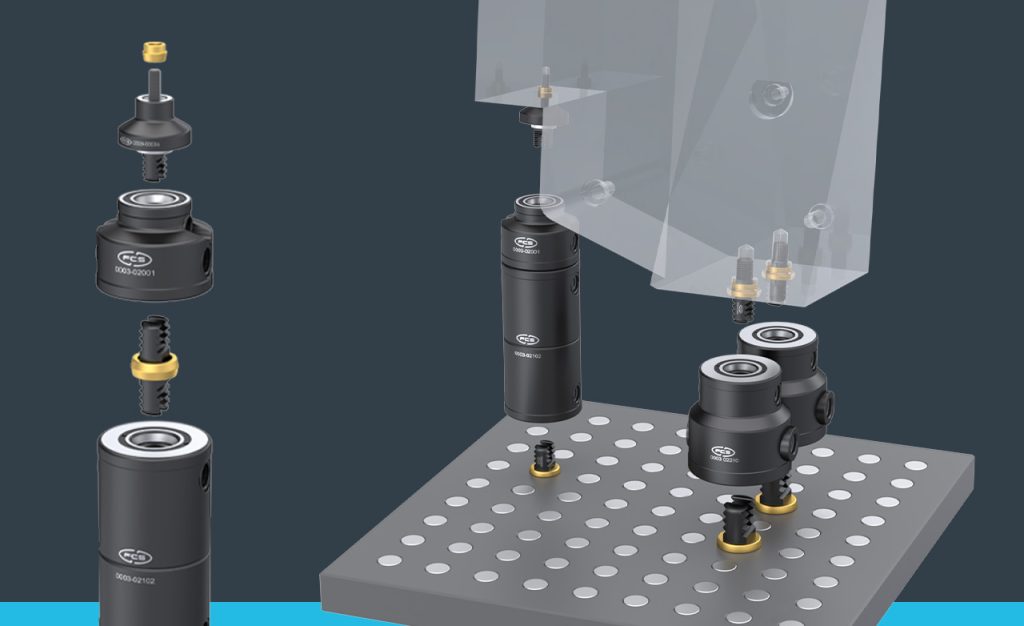

The FCS System has completely revolutionized the Tool and Mold sector.

Born in the heart of a world-leading mold production facility, FCS clamping was able to streamline the manufacturing process across every department including Milling, Deep Drilling, EDM and even Inspection.

The modular, standardized, and user-friendly approach behind FCS grew on a Global scale, and is now fully implemented in facilities around the world.

Why choose the FCS Clamping System for Toolmaking?

In the toolmaking sector, where precision, speed, and flexibility are essential, the FCS Clamping System represents a true revolution. Thanks to its modular design, ease of use, and ability to adapt to complex geometries and machining operations, our clamping system has established itself as the standard for those aiming for excellence and innovation.

1. Hundredth of a millimeter precision

Our system consistently guarantees the exact positioning of workpieces, which is essential for producing high-quality molds and minimizing the risk of non-conformities.

2. Reduced setup times

With fast and modular configurations, the FCS Clamping System allows you to prepare machining operations in record time, increasing productivity and reducing costs.

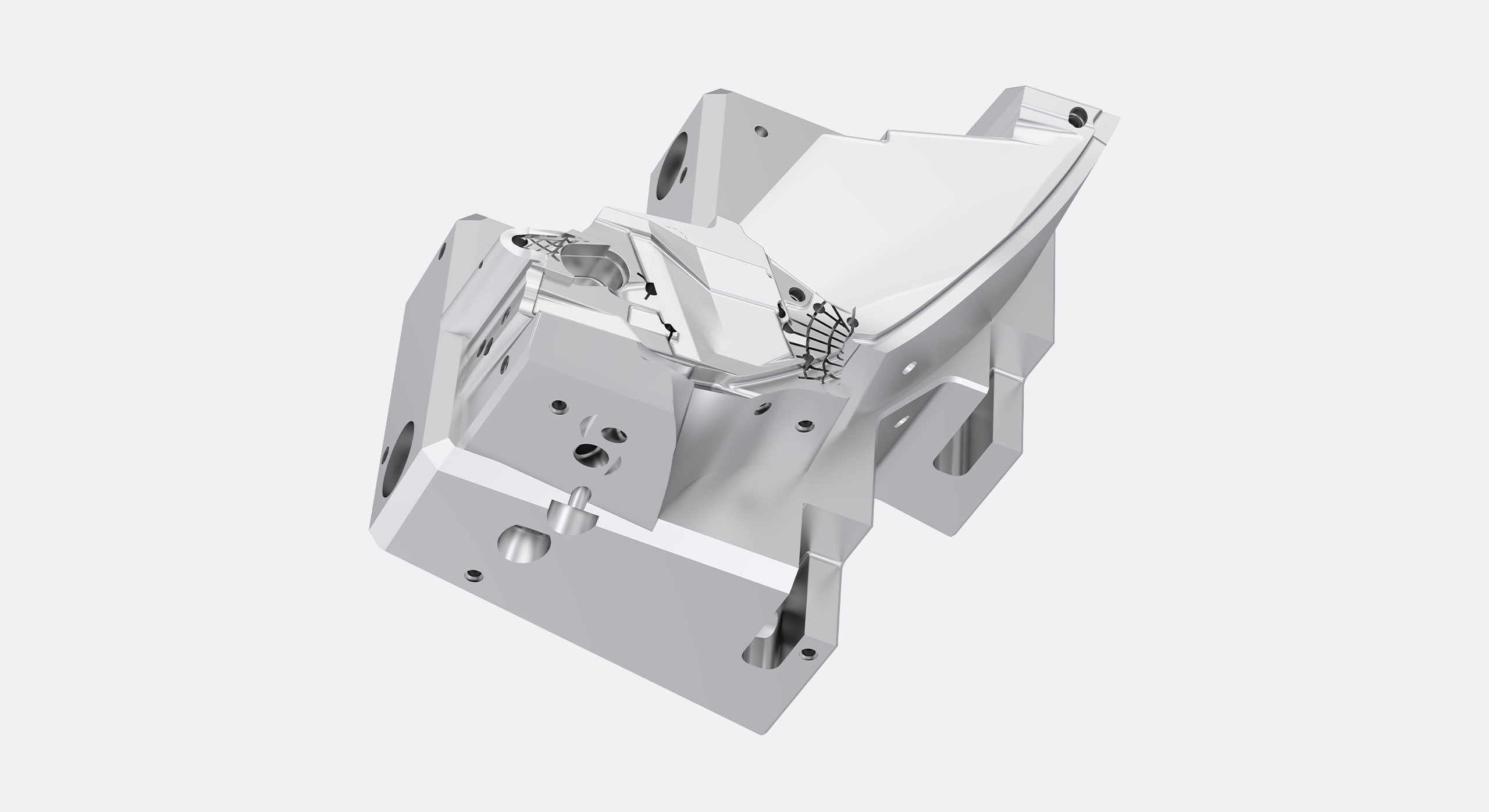

3. Versatility for complex geometries

Thanks to the system’s modularity, components of various shapes and sizes can be clamped without requiring dedicated equipment, significantly simplifying processes.

4. Repeatability and standardization

The system ensures that every process is easily replicable across all machines in your workshop (3, 4, or 5-axis milling machines, drilling machines, sinker or wire EDM, measuring machines) and guarantees that parts can be re-clamped for subsequent operations or modifications without losing reference points, maintaining absolute precision throughout the manufacturing process.

5. Durability and resistance

Made with high-quality materials, our clamping systems are designed to withstand the wear and tear and stresses of intensive machining typical in moldmaking.

Main Applications

Machining of plates and components for all types of molds (plastics, die-casting, metal sheet, etc.)

Prototyping and highly complex machining

Assembly operations and precision dimensional control

With the FCS Clamping System, we empower toolmaking professionals to achieve excellence in every stage of mold and component production. From prototyping to precision assembly, our solutions ensure stability, accuracy, and repeatability.

Case Studies

Have a project to tackle?

Book a meeting with our team and discover how we can help you bring it to life. Together, we’ll find the perfect solution tailored to your needs!