General Mechanics

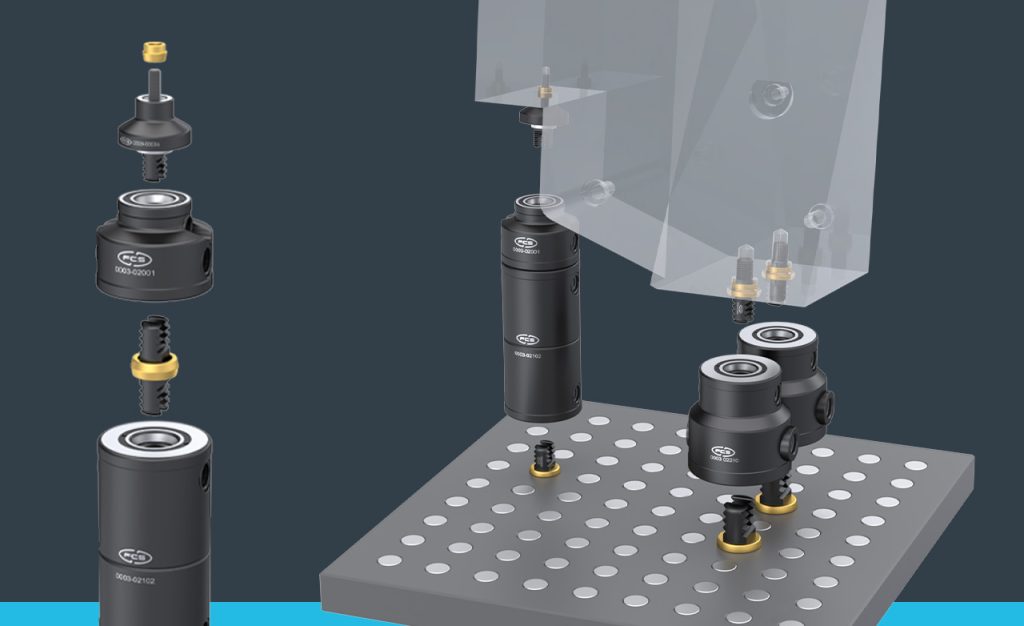

In recent years, FCS System has invested resources and technical expertise to strengthen its presence in the general mechanics sector. Our modularity, and near limiteless combinations mean we will have a solution for any workpiece no matter the size or shape. Whether you aim to process one-off parts or high volume production, the goal remains the same: standardize and simplify the setups.

Our mission? To bring the same technological revolution that has already transformed the moldmaking sector into the heart of general mechanical manufacturing.

Why Choose the FCS Clamping System for General Mechanics?

Our solutions are built on modularity, adaptability, and precision, making them ideal for both high-volume production and single-piece machining with complex geometries. From hardened steel to lightweight alloys, FCS is your reliable partner to improve productivity and reduce hidden setup costs.

1. Adaptability to diverse shapes and sizes

The modular structure allows for flexible and repeatable setups, ideal for machining irregular parts or components requiring multiple operation phases.

2. Reduced setup time

Thanks to the standardized base grid and repeatable connections, setup times are significantly shortened, allowing faster transitions between jobs and improved shopfloor efficiency.

3. Compatibility with CNC and multi-axis machining

FCS is optimized for use with 3-, 4-, and 5-axis machines, ensuring part accessibility and stable fixturing even in highly dynamic cutting processes.

4. Elimination of custom fixtures

Our system provides universal clamping configurations, reducing or eliminating the need for dedicated, costly, and time-consuming custom jigs or fixtures.

5. Full digital integration with CAD/CAM

Each FCS component is available as a precise 3D model, allowing you to simulate and validate your clamping strategy directly within your CAM software.

Main Applications

Machining of forged and cast components

Machining of Welded Frames and Structures

Clamping of Large and Irregular Mechanical Parts

Drilling and Milling of Tubes and Profiles

Precision Machining of Structural Plates and Brackets

Machining of Components Made from Steel, Aluminum, or Composites

With the FCS Clamping System, general mechanics professionals can count on a flexible, scalable, and high-precision approach to fixturing—ensuring faster production cycles and higher repeatability.

Case Studies

COMING SOON

We’re currently working on a selection of case studies that showcase how we solve real challenges for our clients. Stay tuned! the first ones will be published soon.

Have a project to tackle?

Book a meeting with our team and discover how we can help you bring it to life. Together, we’ll find the perfect solution tailored to your needs!