Aerospace

FCS System has recently added a revolutionary product line which focuses on workholding for the most complex geometries in the Aerospace Sector. FCS System has already transformed the world of moldmaking, our Adjustable Clamping is able to do the same for Aerospace machining.

Absolute precision, deformation control, and adaptability are the foundations of our solutions. Machining thin-walled or light alloy materials, such as titanium, aluminum, and composites can have challenges… Our vision is clear: Simplify and standardize the process.

Why choose the FCS Clamping System for Aerospace?

Absolute precision, deformation control, and adaptability are the foundation of our solutions, designed to meet the highest standards of the aerospace industry. Our modular and flexible approach enables efficient handling of even the most complex parts, made from advanced materials such as titanium, aluminum, and composites.

1. Locational adaptability of clamping points:

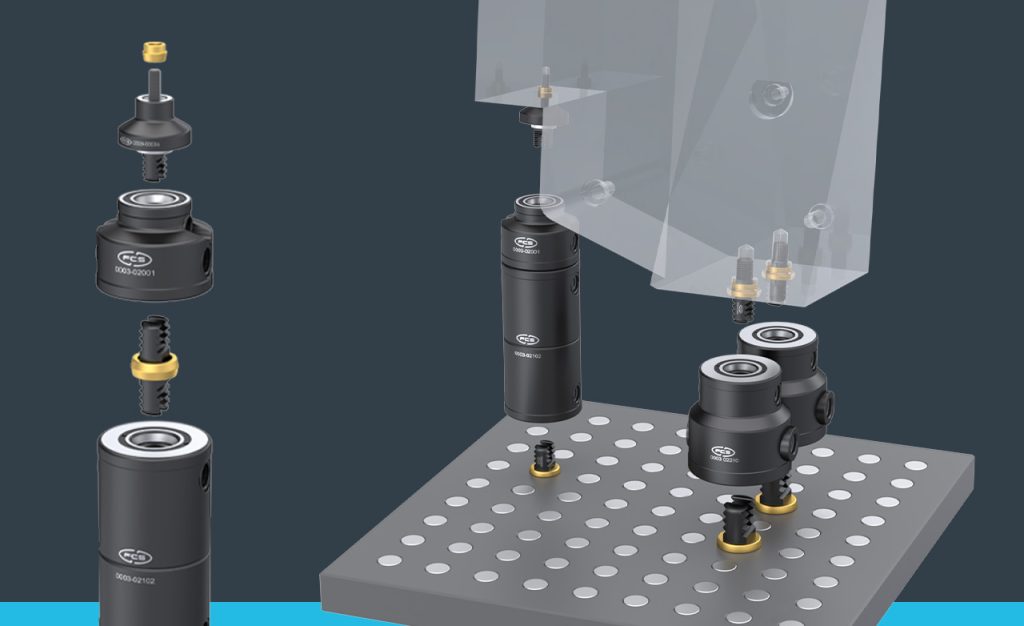

Our Adjustable Clamping System focuses on maintaining a rigid and accurate setup on the most complex geometries while allowing the workpiece to natuarally distort from material removal or thermal deformation. The free movement of the Devices in all axes can completely eliminate the need for shimming resulting in stronger, more precise workholding.

2. Versatility for complex geometries:

Thanks to the system’s modularity and reduction capability, the user is able to reduce the size of the connection to the workpiece without changing the starting grid. This results in highly repeatable, standardized setups.

3. Professional support:

Our experienced team will work with you to create a full CAD design clamping environment tailored to your specific workpiece(s).

4. Simplifying the quoting process:

By standardizing the workholding around your part, you will be able to accurately estimate workpiece setup time leading to more precise and competitive quoting.

5. Precise CAD data available:

Having an accurate representation of your workholding environment is critical in avoiding costly errors. Each FCS component is paired with an accurate 3D model. Using this, you are able to replicate the exact conditions you will find in your machine.

6. Eliminate custom Fixturing:

With the limitless combinations of FCS, you will be able to find a workholding solution on any workpiece and remove the need to build custom or one-off fixturing.

Main Applications

Machining of aircraft/aerospace parts with precision tolerances

Clamping components made of light alloys

Thin walled parts that can experience thermal or material removal deformation

With the FCS Clamping System, we support aerospace industry leaders in transforming their processes by delivering reliability, innovation, and competitiveness. Choose a partner who understands the challenges of the sector and provides concrete solutions to overcome them successfully.

Case Studies

Have a project to tackle?

Book a meeting with our team and discover how we can help you bring it to life. Together, we’ll find the perfect solution tailored to your needs!