Clamping System

Flexible Clamping Solutions

We deliver specialized solutions aimed at optimizing clamping systems for high-performance manufacturing. Our services are structured around two core offerings

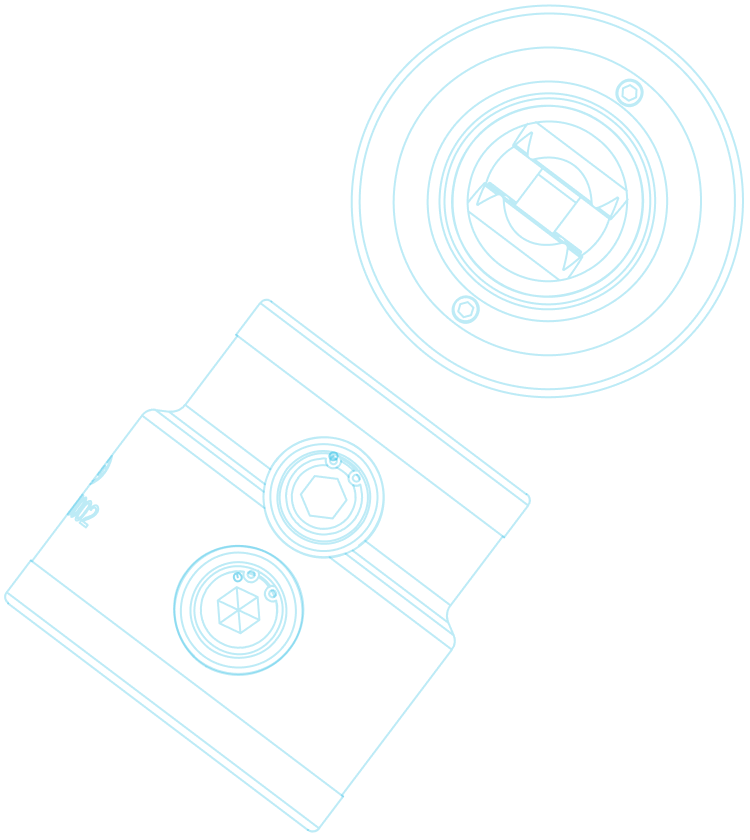

CNC Machine Equipment Solutions

Based on the specifics of the machine and the size range of the workpieces, we provide a set of clamping components and an optimized manufacturing methodology that enhance resource utilization and operational efficiency.

Process Application Solutions

- Clamping configurations as well as recommendations on extra material allowances for each manufacturing stage

- Stress-relief techniques and workpiece alignment strategies

- Remote assistance and on-site support

Unlock your potential, making FCS lock the workpiece

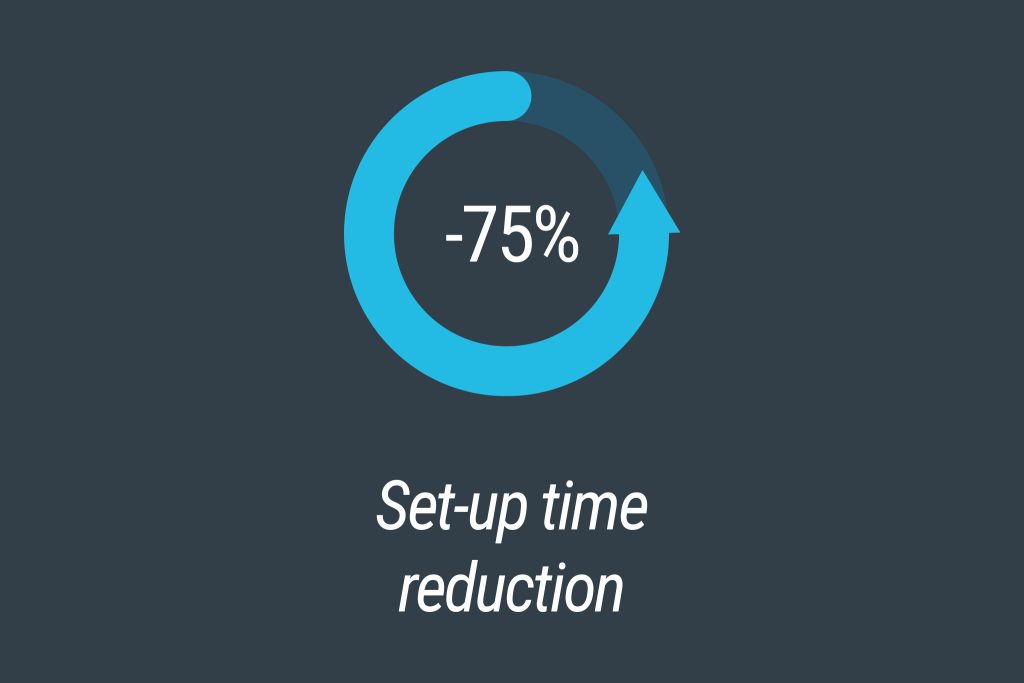

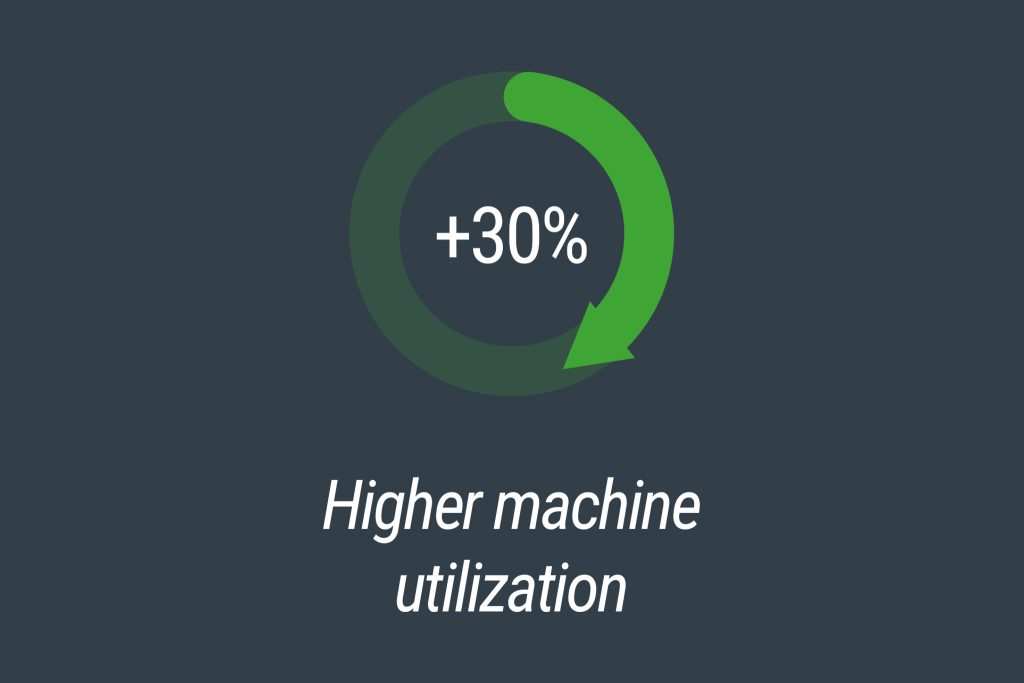

Discover the advantages of FCS systems. Our modular clamping technology optimizes setup times, enhances machining accuracy, and boosts productivity across all manufacturing sectors. FCS helps unlock your full potential by making every setup fast, safe, and reliable.

Performance

Setting Up

CAD/CAM Simulation

It allows to solve issues upstream (in the virtual stage – CAD/CAM) that would otherwise arise downstream (in the real process – Production department)

Assembling optimization

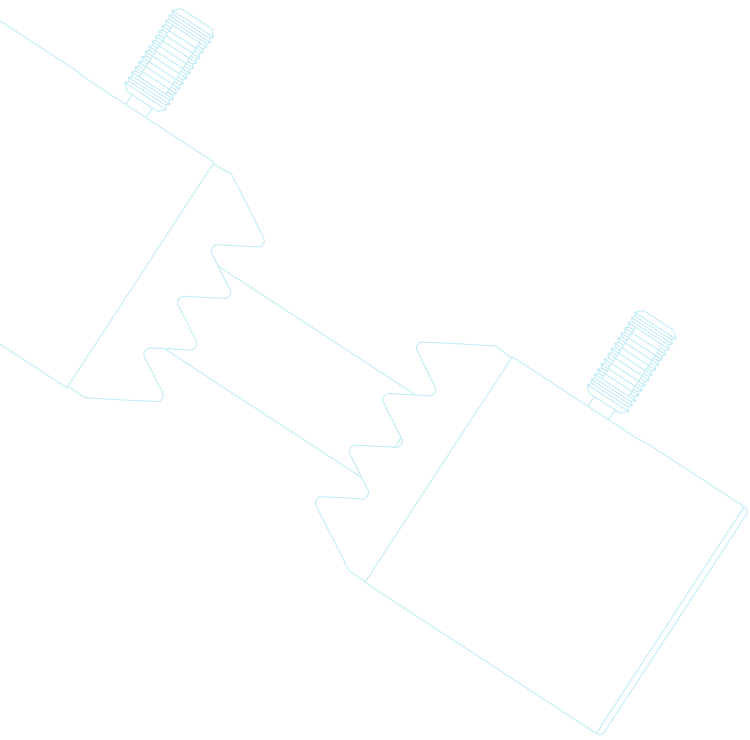

The components have been made to be easily and quickly assembled.

Workpiece positioning and orientation

The clamping system framework allows to keep track of the position and orientation of the workpiece with high accuracy along the production process.

OPs reduction

Thanks to:

– the machining accessibility increasement;

– the stress relieving management caused by the metal cutting

Cutting

Machining accessibility (up to 5 free-faces)

High accessibility to machine the workpiece (minimized obstacles/interference issues).

Optimal clamping force

The clamping system ensures strength and rigidity without causing any geometric deviation to the workpiece.

Minimized cutting tool vibrations

The clamping components are designed to dampening the vibrations.

Cycle-time (Run time) reduction. MRR (Metal Removal Rate) increasement

As a consequence of the points above.

Compliance

Accuracy on reaching the requested tolerance and roughness

The clamping components are manufactured with high accuracy in order to transfer it to the workpiece alignment (high angular and linear position accuracy of the workpiece). The roughness is strictly depending on the capability to minimize the vibrations.

Risk of collisions minimised

As result of minimizing obstacles around the workpiece and keeping position references.

Keep the position and orientation references all over the process

It helps to input correctly the zero CAM.

Structure and Functions

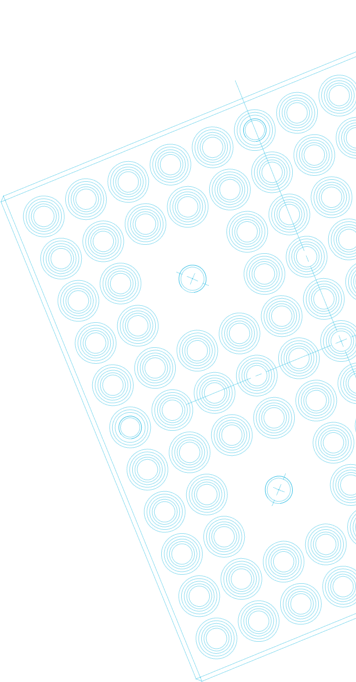

Modular, standardized and proportional to the workpiece size

If the machine working area is capable to include more parts together, the clamping system is configurable to clamp individually more parts with many options.

Lends it self to new developments and to be easily interconnected with not FCS product

The clamping system, is designed to be furtherly extended to include additional components (even if they are not FCS components).

Very low and easy maintenance

It requires simple interventions (daily cleaning, monthly rust prevention oil and only a few spare parts may need to be replaced).

Automation

Further increasement of the production volume and of the efficiency

Quick workpiece changeover, by means of multipallet and automatic clamping system allow to increase the efficiency and the production volume.

Production Chain

Adopting the same production method

Extending the same clamping approch internally in the production workflow and externally (in outsourcing) further (synergical) benefits are achieved.

Profitable

Investment

Short pay back period

The breakeven point (time it takes to recover the cost of the clamping components) can be reached within 6 till to 18 months.

Durability

If properly used and maintained the clamping components have long-lasting (more than 10years).

Emotional

Perceptiveness

Improving of the working environment

The use of FCS clamping components is similar to Lego, and the starting grid resembles the game Battleship

Have a project to tackle?

Book a meeting with our team and discover how we can help you bring it to life. Together, we’ll find the perfect solution tailored to your needs!