Toolmaking 01

Home » Case Studies » Toolmaking 01

Customer request

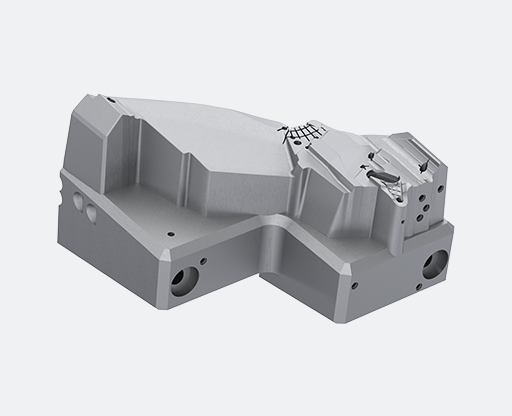

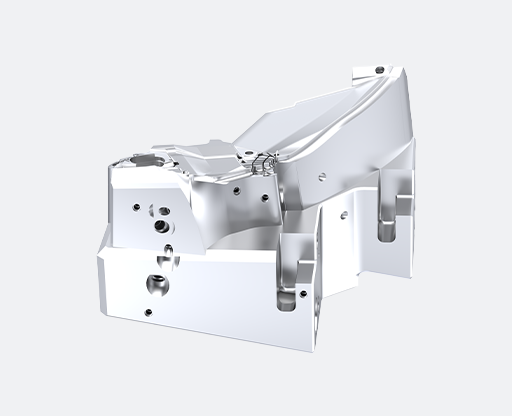

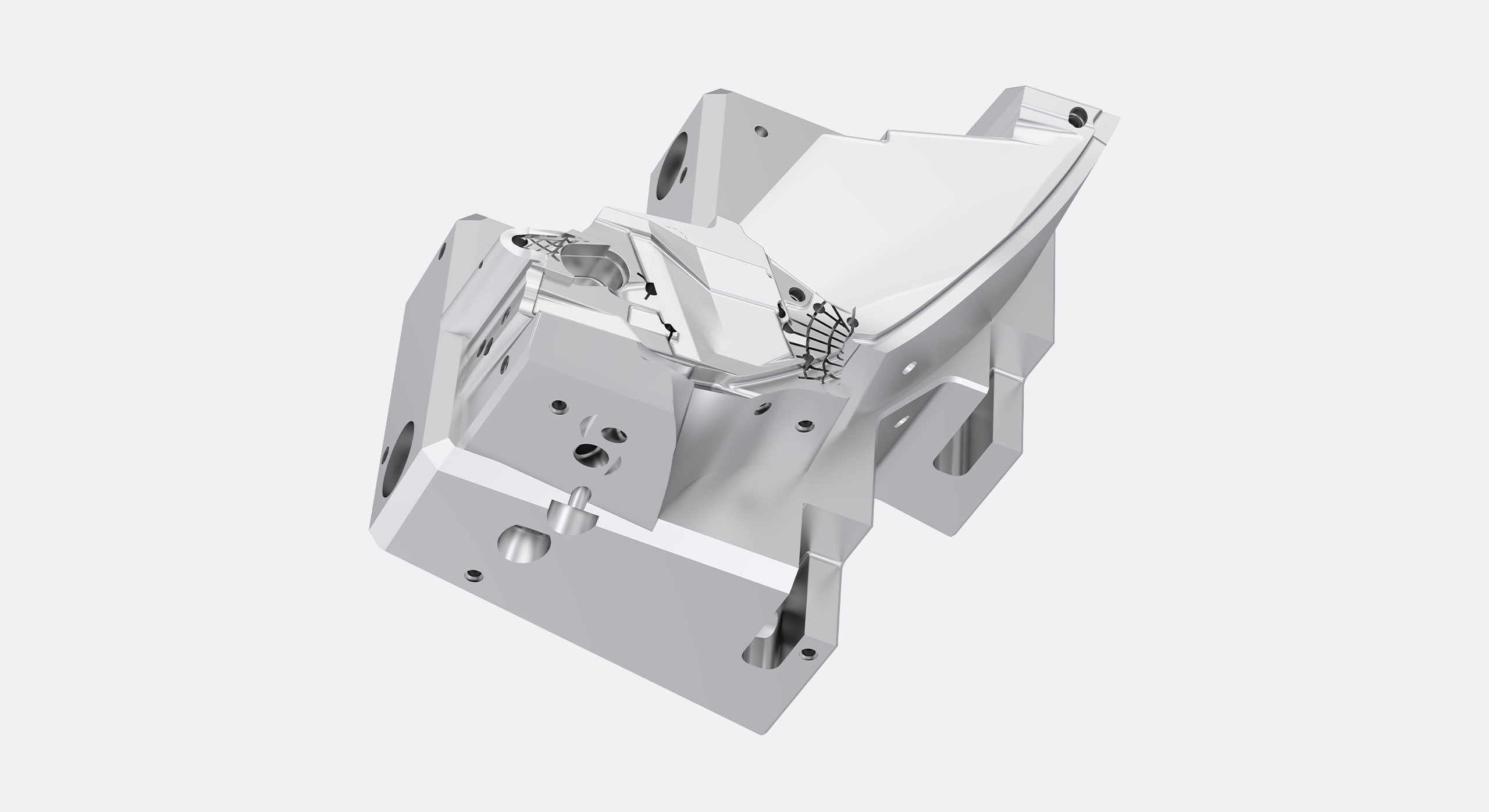

Injection mold slide to be manufactured as a one-off part by machining, from solid stock.

The component features highly complex geometry on its outer profile and internally it contains a high density of holes and pockets (for cooling, guiding movements and making connections).

Furthermore, the manufacturing process includes hardening, which causes a geometric deformation.

What the customer asked

A different method from toe clamps and dedicated fixtures due to the following usage limitations

Toe clamps: reduced tool access for material removal and longer set-up time

Dedicated fixtures: not cost-effective for one-off production

Avoid using metal foil shims after heat treatment for alignment purpose

Quick clamping and alignment in case of rework

Our solution

High efficiency process in eight stages (including quality control and polishing).

Manufacturing Process Overview

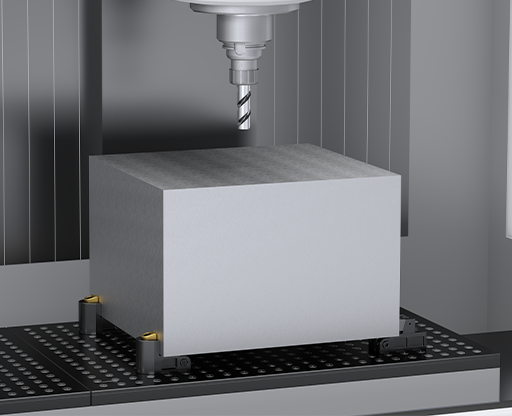

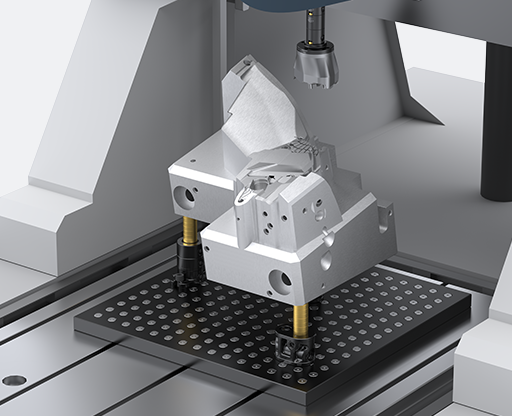

OP 10

Machining:

Roughing till to +3mm and drilling.

Clamping equipment:

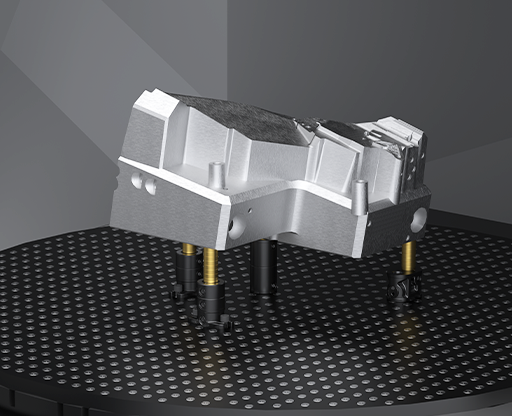

Bottom reference Base Gauges M16 and Modular Grip vise.

OP 20

Machining:

Roughing till to +3mm.

Clamping equipment:

Bottom reference Custom Base Gauges M16, Fixed and Support Clamps.

OP 30

Heat treatment:

Hardening.

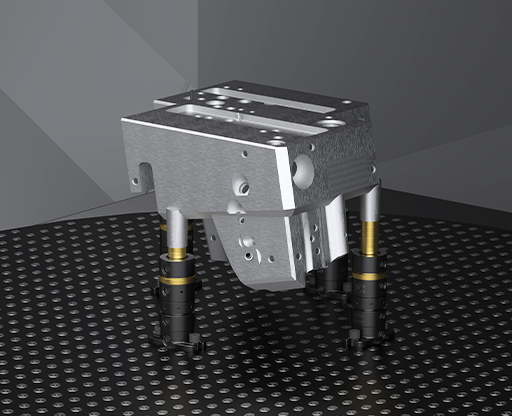

OP40

Machining:

Finishing.

Clamping equipment:

Bottom reference custom Base Gauges M16 and Adjustable clamps to manage the deformation caused by hardening.

OP50

Machining:

Finishing.

Clamping equipment:

Bottom reference custom Base Gauges M16, Fixed and Support Clamps.

OP60

Machining:

EDM Sinker.

Clamping equipment:

Bottom reference Base Gauges M16 800x800mm, Fixed and Support Clamps.

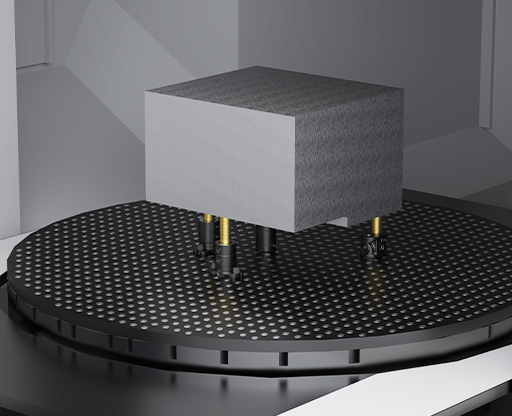

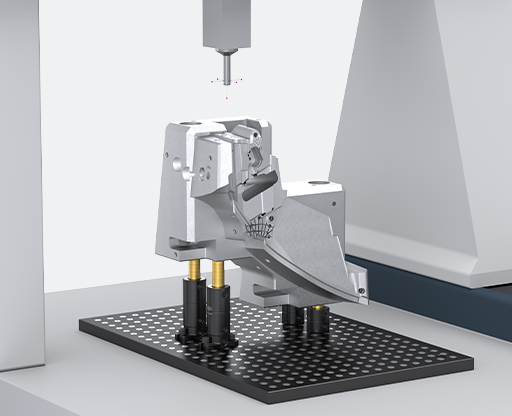

OP70

Quality Control:

CMM (Coordinate-measuring machine)

Clamping equipment:

Bottom reference Base Gauges M16 1000x400mm and Fixed Clamps.

OP80

Treatment:

Polishing.

Additional Resources

Technical Project Data

- Sector: Toolmaking

- Material Type: Steel 1.2343

- Raw Block overall size: 635x695x452 mm

- Finished Part overall size: 630x689x447 mm

- Raw block weight: 1566 kg

- Finished part weight: 440 kg

- Material removal index (MRI): 72%

- Accuracy: 0,02 mm

Classification Tags

- Material Category: Steel

- Accuracy: High

- Material removal index (MRI): Medium

Have a project to tackle?

Book a meeting with our team and discover how we can help you bring it to life. Together, we’ll find the perfect solution tailored to your needs!