Aerospace 01

Home » Case Studies » Aerospace 01

Customer request

The deformation caused by metal cutting together with the high accuracy could drive to make longer the manufacturing process and increase the risk of rejects. These manufacturing losses can be minimized achieving optimal efficiency through the innovative clamping and machining methodology described below.

What the customer asked

Ensure the requested accuracy

Reduce the total cycle time

Reduce the total set-up time

Reduce the manufacturing stages (OP)

Managing deformation (Avoid Shimming)

Standard production methods

Reconfigurable set-up

Short pay-back period

Our solution

High efficiency process in three machining stages (plus lugs removal and polishing).

Whitstanding to keep well hold the workpice without forcing its geometry, clamping adaptability for handling the stress relieving coming from the metal cutting deformation and control of the alignment. Quick and manual locking-unlocking. In addition the clamping components can be used for other applications (reconfigurable equipment).

Manufacturing Process Overview

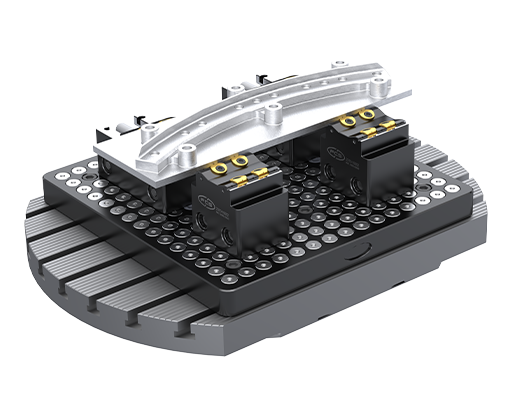

OP 10

Machining:

Roughing till to +1mm from the finished geometry.

Clamping equipment:

Bottom reference plate 400x400mm and Modular (Double Module) vises (gripping height 5mm) .

OP 20

Machining:

Roughing on the top side, leaving enough extra material (according to the expected deformation). Stress relieving. Finishing.

Clamping equipment:

Bottom reference plate 400x400mm and Body adjustable M12 H120 + Body reduction M12-M6 H30.

OP 30

Machining: Finishing

Clamping equipment: Pallet 400x400mm and fixed Body M12 H120 + Body reduction M12-M6 H30.

LUGS REMOVAL AND POLISHING

The extra material left to make the connection with the supports will be partially cutted by milling as last operation at the stage OP30 and then remove manually and polished.

Additional Resources

Technical Project Data

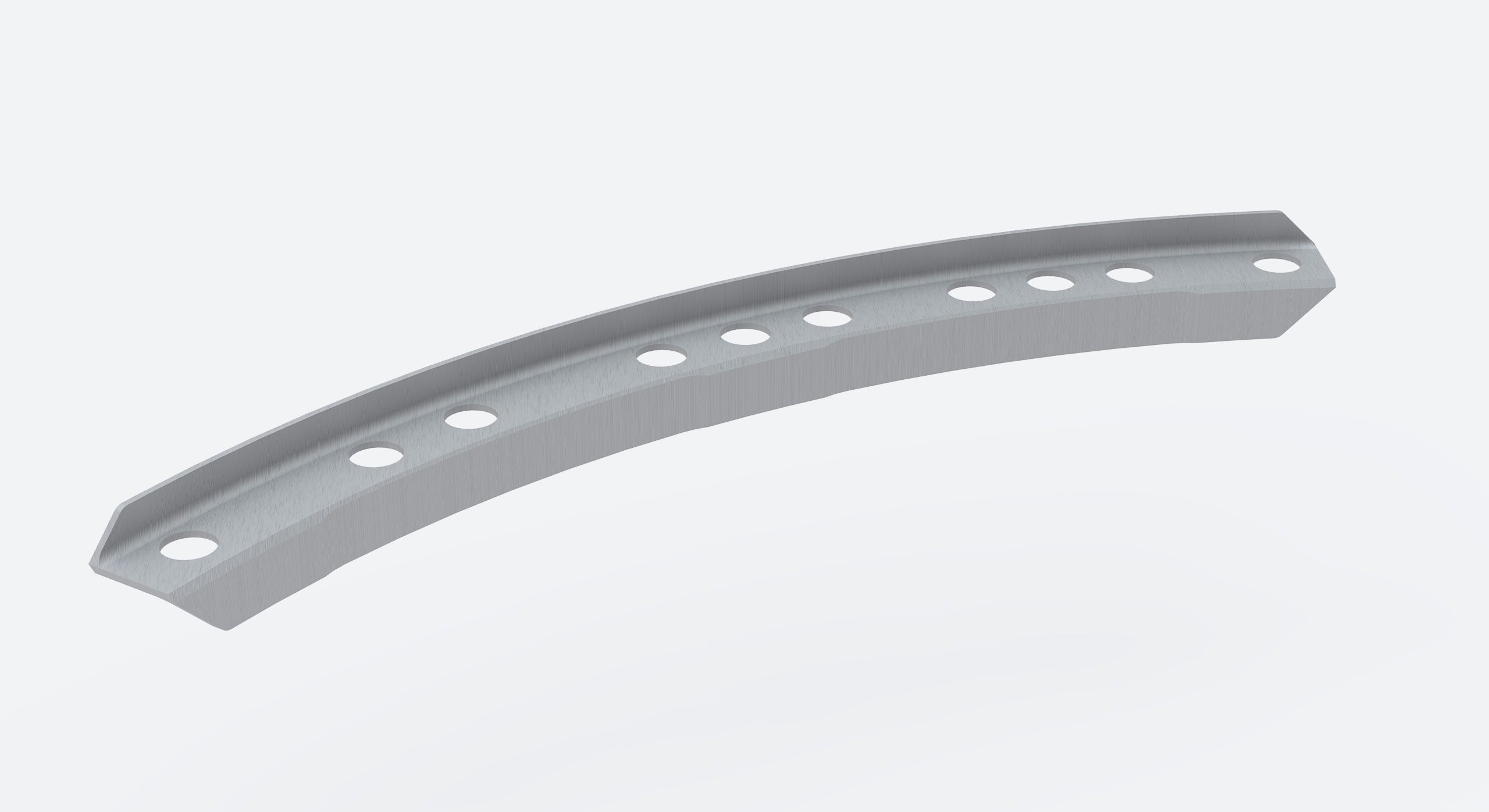

- Sector: Aerospace

- Material Type: Aluminum 7075

- Raw Block overall size: 400x130x35 mm

- Finished Part overall size: 396x76x30 mm

- Raw block weight: 4,9 1kg

- Finished part weight: 0,24 kg

- Material removal index (MRI): 95%

- Accuracy: 0,01 mm

Classification Tags

- Material Category: Light Alloy

- Accuracy: High

- Material removal index (MRI): High

Have a project to tackle?

Book a meeting with our team and discover how we can help you bring it to life. Together, we’ll find the perfect solution tailored to your needs!